American business leaders just got the wake-up call of their lives.

What they witnessed left them genuinely terrified for their companies’ survival.

And Ford’s CEO was scared for his company’s future after one shocking factory trip.

Western executives witness manufacturing revolution that leaves them "humbled"

Ford Motor Company CEO Jim Farley has been making trips overseas six or seven times a year to study the competition.¹

But his most recent visits left him shaken in ways he never expected.

"It’s the most humbling thing I’ve ever seen," Farley admitted.²

The automotive giant’s chief executive wasn’t alone in his alarm.

Greg Jackson, head of British energy supplier Octopus, described touring a factory that operated with barely any humans in sight.³

"We visited a dark factory producing some astronomical number of mobile phones," Jackson explained.³

"The process was so heavily automated that there were no workers on the manufacturing side, just a small number who were there to ensure the plant was working."³

Australian mining billionaire Andrew Forrest abandoned his electric vehicle powertrain project after seeing what these factories could do.⁴

These aren’t small-time operators getting spooked by flashy presentations.

These are titans of Western industry who’ve seen it all – and what they witnessed overseas left them genuinely worried about their companies’ futures.

China’s automation advantage threatens American industrial survival

Farley brought his entire Ford leadership team on these overseas trips, where they drove the latest vehicles and studied the competition.⁵

What they found wasn’t just impressive – it was years ahead of anything American manufacturers are producing.

"Their cost and the quality of their vehicles is far superior to what I see in the West," Farley warned.²

The vehicles packed cutting-edge self-driving software and facial recognition systems that know which seat someone’s in and adjust media preferences automatically.²

Chinese manufacturers have mastered in-vehicle technology in ways that leave Western brands scrambling.⁵

Drivers get in and their phones pair automatically, their entire digital life mirrored in the car, with an AI companion equivalent to ChatGPT handling everything from navigation to entertainment.⁵

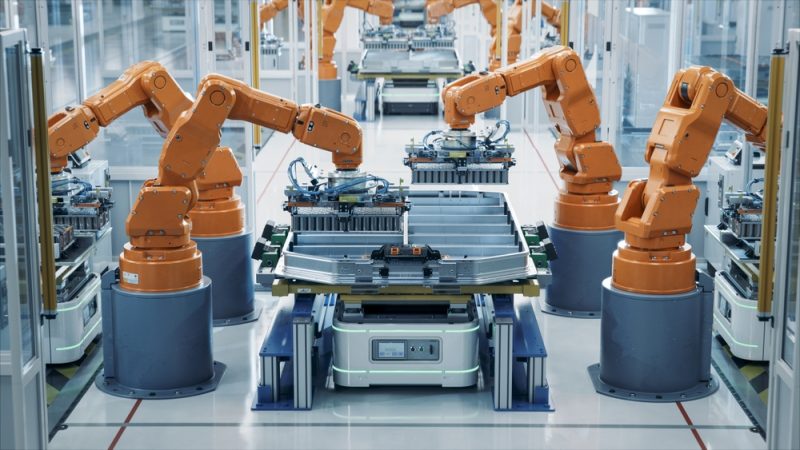

But the real shock came when executives toured the factories themselves.

Forrest described facilities where robots rise from the floor and assemble trucks with zero human involvement.⁴

"I can take you to factories now, where you’ll basically be alongside a big conveyor and the machines come out of the floor and begin to assemble parts," Forrest said.⁴

"And you’re walking alongside this conveyor, and after about 800, 900 metres, a truck drives out. There are no people – everything is robotic."⁴

These aren’t traditional assembly lines with some automation mixed in.

These are "dark factories" – facilities that operate 24/7 in near-total darkness because no humans are present who need light to see.⁶

The robot density tells the story: China reached 392-470 robots per 10,000 manufacturing workers compared to America’s 274.⁷

In 2022 alone, China installed 290,367 industrial robots – accounting for 52% of the worldwide total.⁷

America faces existential manufacturing crisis as China dominates global production

The numbers paint a grim picture for American industry.

China now controls 70% of global electric vehicle production.⁵

But the threat extends far beyond automotive.

Chinese manufacturers accounted for nearly 30% of global manufacturing output in 2024.⁸

By 2030, China is projected to account for 45% of the world’s industrial production.⁹

Meanwhile, the United States is forecast to drop from 25% of global manufacturing in 2000 to just 11% by 2030.⁹

This isn’t happening by accident.

Beijing’s "Made in China 2025" initiative prioritizes robotics and AI-driven manufacturing, backed by $1.4 billion in government investment for robotics research and development in 2023 alone.⁷

Companies like Foxconn replaced 60,000 workers with robots in a single factory and aims to automate 30% of its operations.¹⁰

Xiaomi’s smart factory in Changping produces one smartphone per second using AI and robotics, with an annual production capacity of 10 million devices from an $330 million facility.¹¹

The strategic advantage compounds over time.

When robots build products faster and cheaper than human workers, that’s one level of competition.

But when those robots are building other robots in fully automated facilities, creating a self-sustaining automation ecosystem, the gap becomes nearly impossible to close.¹²

American CEOs sound alarm but Washington remains asleep at the wheel

Farley put the stakes in blunt terms during his assessment.

"We are in a global competition with China, and it’s not just EVs," Farley stated.²

"And if we lose this, we do not have a future at Ford."²

Wall Street analysts expect the humanoid robotics market to hit $5 trillion by 2050.⁴

Morgan Stanley projects over 1 billion humanoids in operation by that date, with nine out of ten working factory floors and commercial facilities rather than homes.⁴

Chinese robotics firm Unitree controls 60% of the global quadruped robot market right now.⁴

Boston Dynamics and other American players are trying to catch up, but the gap keeps widening.⁴

What makes this so dangerous for American companies isn’t just the cost savings.

Dark factories run 24/7 without breaks, lunch hours, or shift changes.⁶

No workers means no lighting bills, no HVAC costs, no safety equipment.⁶

The facilities cut energy use by 15-20% while cranking out higher quality products than human assembly lines ever could.⁶

American manufacturers are staring down a hard truth: the technology gap may be too wide to close now.

Every month China builds more automated capacity while U.S. factories still depend on human workers who cost more and produce less.

For decades, American business leaders assured themselves that innovation and quality would always trump cheap Chinese labor.

That comfortable assumption just died in those dark factories overseas.

The question now isn’t whether America can compete with China’s manufacturing might.

The question is whether American companies like Ford will survive the decade ahead.

¹ Inside EVs, "The Most Humbling Thing I’ve Ever Seen: Ford CEO On China’s Car Industry," June 30, 2025.

² The Telegraph, "’Most Humbling Thing I’ve Ever Seen’: Western Business Leaders ‘Terrified’ After Touring Chinese Factories," October 14, 2025.

³ Ibid.

⁴ Ibid.

⁵ Inside EVs, "The Most Humbling Thing I’ve Ever Seen: Ford CEO On China’s Car Industry," June 30, 2025.

⁶ Foreign Affairs Forum, "China’s Dark Factory Revolution: The Rise of Fully Automated Manufacturing Without Workers or Lights," March 19, 2025.

⁷ Unite.AI, "Dark Factories and the Future of Work: How AI-Driven Automation is Reshaping Manufacturing," March 26, 2025.

⁸ IndustryWeek, "What Can the US Learn from China’s Manufacturing Growth?"

⁹ Coalition For A Prosperous America, "China’s Manufacturing Share to Hit 45% by 2030 as U.S. Falls to 11%, Report Warns," February 11, 2025.

¹⁰ Unite.AI, "Dark Factories and the Future of Work: How AI-Driven Automation is Reshaping Manufacturing," March 26, 2025.

¹¹ Ibid.

¹² Stelia AI Newsroom, "Dark Factories Rising: How China’s Robot Revolution is Reshaping Manufacturing," March 11, 2025.